There is a high incidence of failure of certain designs of component on filling stations as revealed by routine high precision testing now being carried out. A failure of a component causes the failure of the system, rectification and the cost of a further test. Such experiences help no one: not the client, not the component manufacturer, not the tester – and they can so easily be avoided.

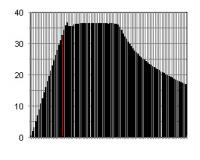

The graph shows the behaviour of a leaking PV valve following pressurisation above its opening pressure and subsequent release. Readings of pressure and temperature at 200 millisecond intervals have been taken automatically by the MassTech International test system. The leak caused the failure of a vapour recovery test. The same design of valve has failed many times but not always. By testing and certificating components beforehand either on the clients initiative or better on the manufacturer’s:

- The incident of equipment failure becomes insignificant.

- System test failures such as the vapour recovery test become fewer and more meaningful.

- The manufacturer’s reputation rises.

MassTech reports identify the reasons for failures before supply to the client allowing design or manufacturing procedures to improve.

If the client purchases equipment without test certification, incidence of system failures due to single component failure can still be prevented by prudent action. Call MassTech International for detail