It is logical that those systems, which are designed to retain spills, are periodically tested and proven to be tight and this is a logical extension to the work of a tank and line testing company.

The basins are made of both steel and plastic and are installed on fill risers and remote fill pipes of the UST. Most basins have a five-gallon spill capacity; however, larger basins with capacities upwards of twenty-five gallons are available. Some have drains or hand pumps permanently installed while others require the use of an external pump or absorbent pads to remove product.

It is important to understand that basins were neither intended nor designed for the storage of petroleum product, but rather to contain a small spill. The clear intent is that any spilled product would be immediately removed and either returned to the tank or properly disposed.

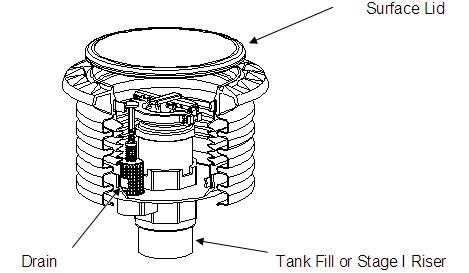

The following is a schematic of a typical basin:

A typical testing procedure includes the elements:

- The basins are hydrostatically tested;

- Care must be taken to isolate loss through the drain;

- The standard for declaring a failure is 1/8 inch or greater loss of water within one hour (which is equal to a leak rate of 0.05 gallons per hour in a typical 12-inch diameter basin).

MassTech International and its licensees and technicians are qualified to test sumps and spill containment systems as required in many territories.